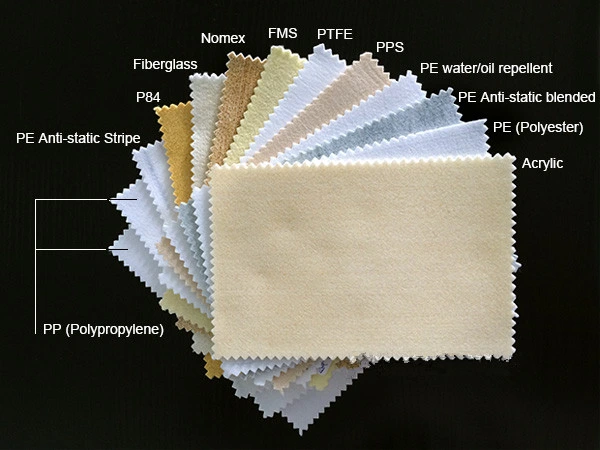

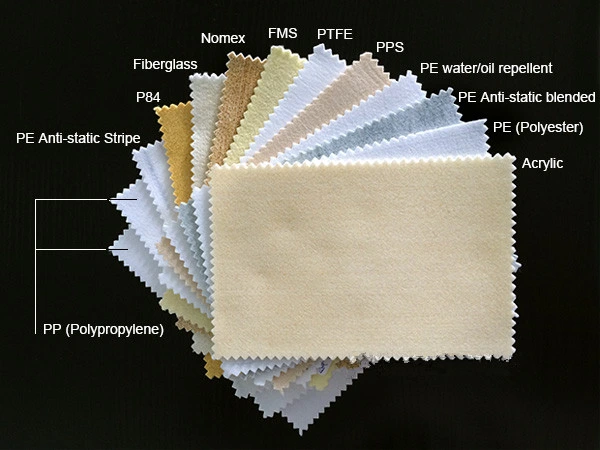

Power plant filter bags PPS filter bag Ryton felt filter Surface treatmeng :

Specification of PPS Filter Bag:

Fabric: PPS fiber (polyphenylene sulfide)

Temperature resistance: up to 200ºC (392ºF)

Area weight (g/m2): 350~700

Thickness (mm): 1.2~2.4

Filtration precision: ≤30mg/nm3

Working lifetime: 8000 hours and more

Diameter & Length: No limited

MOQ: 50pcs. Support retail, and freight is on your own account.

Features of PPS Filter Bag:

The acid and alkali resistance is Excellent. Meanwhile, PPS fiber does not burn, neither does it support burning. The temperature resistance is up to 200ºC (392ºF).

The resistance to oxidation is poor. So the working environment requires the oxygen content less than 14%(Vol.), and the oxynitride content is less than 600mg/Nm3. The higher oxygen contents the lower working temperature.

Physical properties:

Chemical properties:

Fabric: PPS fiber (polyphenylene sulfide)

Temperature resistance: up to 200ºC (392ºF)

Area weight (g/m2): 350~700

Thickness (mm): 1.2~2.4

Filtration precision: ≤30mg/nm3

Working lifetime: 8000 hours and more

Diameter & Length: No limited

MOQ: 50pcs. Support retail, and freight is on your own account.

Features of PPS Filter Bag:

The acid and alkali resistance is Excellent. Meanwhile, PPS fiber does not burn, neither does it support burning. The temperature resistance is up to 200ºC (392ºF).

The resistance to oxidation is poor. So the working environment requires the oxygen content less than 14%(Vol.), and the oxynitride content is less than 600mg/Nm3. The higher oxygen contents the lower working temperature.

Physical properties:

| Air permeability(L/m2.s) @200pa | Tensile strength(N/5cm) | Temperature(ºC) | ||

| warp | weft | continue | instant | |

| 150~300 | 900 | 1100 | 190 | 200 |

| Acid Resistance | Alkali Resistance | Hydrolytic Resistance | Oxidation Resistance | Abrasion resistance |

| Excellent | Excellent | Excellent | Poor | Good |

Applications :

• Coal - Fired Boilers bag houses

• Municipal Solid Waste Boilers and Waste incinerator baghouse filter

• Calciners / Catalysts

• Thermal power plant

• Waste to energy

• Iron and non ferrous Metal Industry.

1. Water and oil repellent treatment: A substantial increase in performance of water and oil repellent

2. Acrylic coating: A substantial increase in Abrasion resistance property

3. Carbon coating: Anti-spark

4. PTFE film: Improve filtration precision: ≤5gsm/Nm3, but lower the filtration efficiency; and a substantial increase in acid-base resistance property

5. PTFE paint-coating: Improve filtration precision: ≤10gsm/Nm3, does not lower the filtration efficiency; and a substantial increase in acid-base resistance property

6. PTFE dipping: Improve filtration precision: ≤25gsm/Nm3, does not lower the filtration efficiency; and a small increase in acid-base resistance property

2. Acrylic coating: A substantial increase in Abrasion resistance property

3. Carbon coating: Anti-spark

4. PTFE film: Improve filtration precision: ≤5gsm/Nm3, but lower the filtration efficiency; and a substantial increase in acid-base resistance property

5. PTFE paint-coating: Improve filtration precision: ≤10gsm/Nm3, does not lower the filtration efficiency; and a substantial increase in acid-base resistance property

6. PTFE dipping: Improve filtration precision: ≤25gsm/Nm3, does not lower the filtration efficiency; and a small increase in acid-base resistance property

We are factory , we are make as per your needs.

Our other other products

Our other other products

If you have any question, please feel free to contact me.

Contact information :

Name : Queenie

Cellphone no :0086-13395199868