Focusing on OEM Service of solid and liquid silicone rubber and related products for 26 years ,

we are specialized in R&D and production of every product basing on clients'design or idea totally.

OEM Part Description

OEM Relative Projects

Manufacturer Strength Showing

Manufacturer Certificates showing

OEM Advantage Description

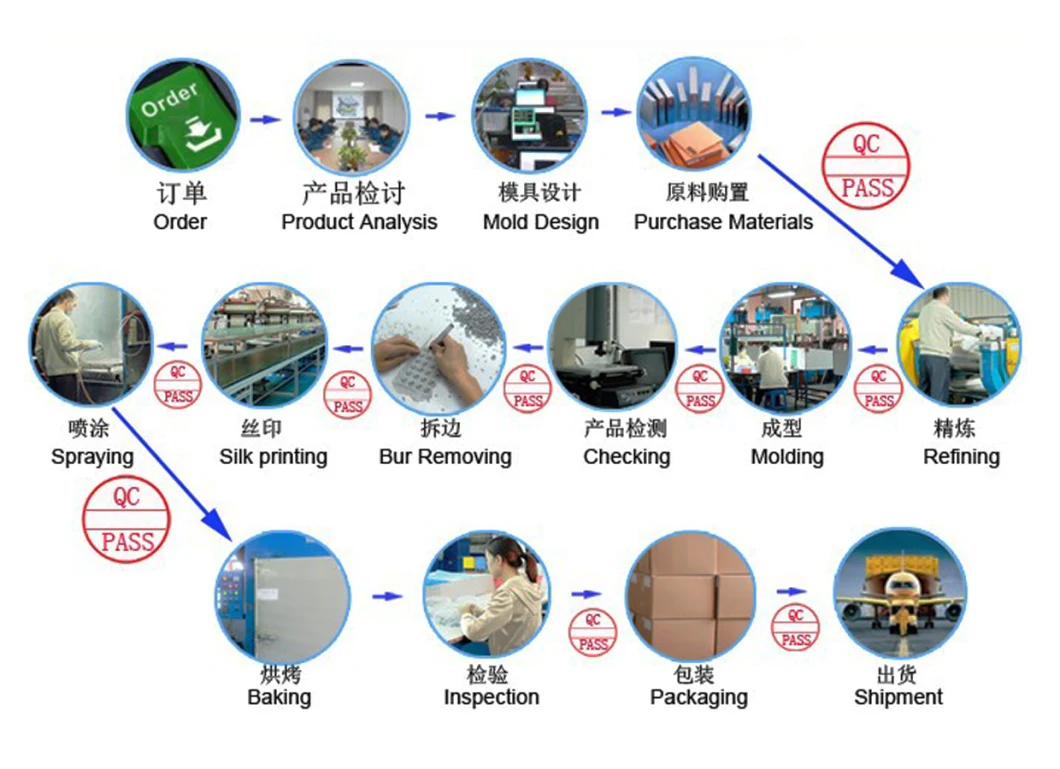

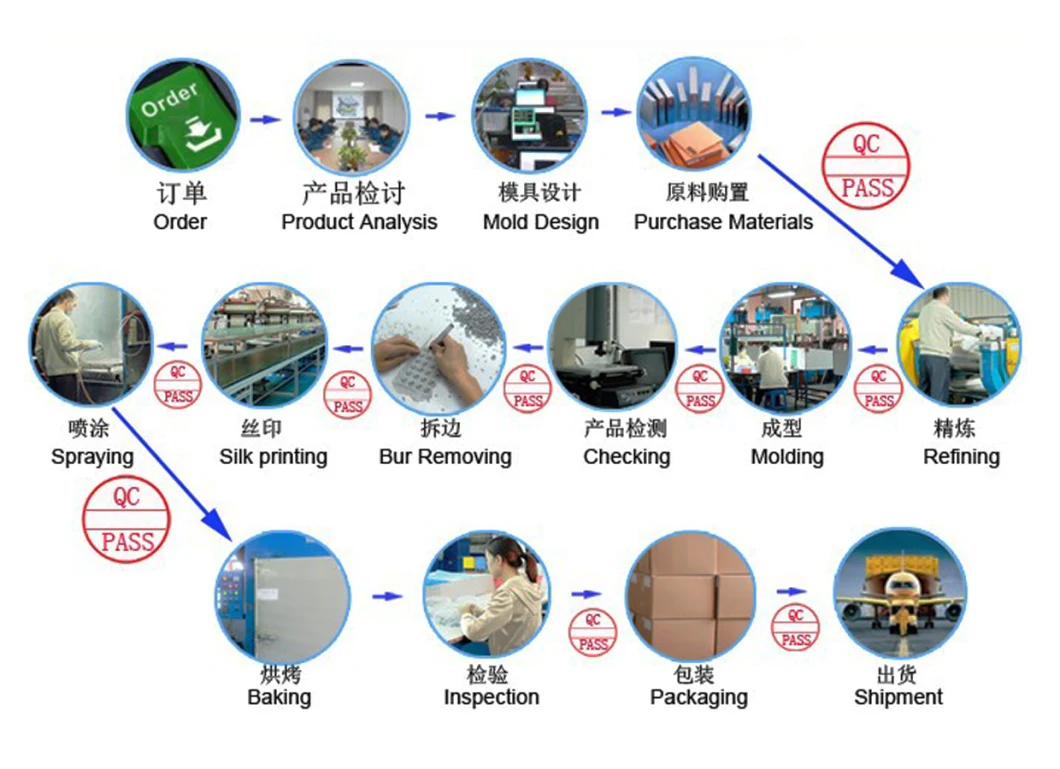

OEM process showing

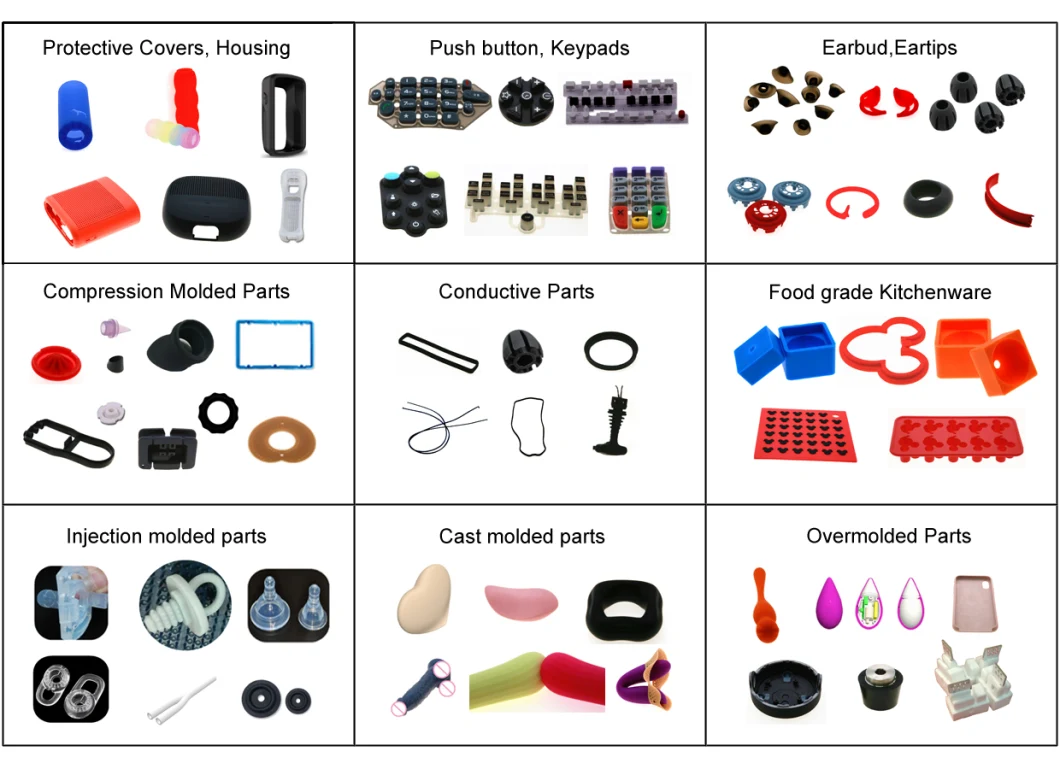

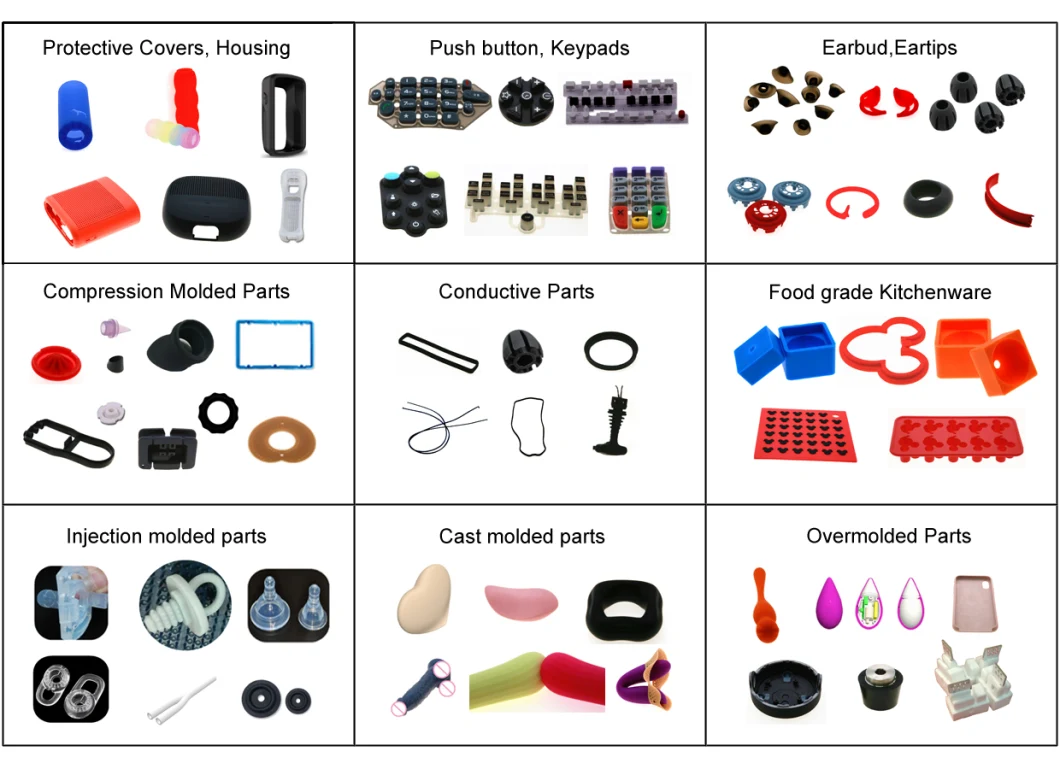

OEM Scope Showing

FAQ

Q: Are you trading company or manufacturer ?

A: We are OEM factory of customizing solid and liquid silicone rubber products and related products.

Two options: #1.. Make tool and produce products according to your own design.

#2.. Design 3D file basing on your idea, sketch or samples then go through #1.

Q: what is the color standard we are using?

A: Pantone color and RAL color or color chip.

Q: How long is the production circle?

A: Normally,Test mold: 5~15 working days, MP mold:10~25 working days;

Mass production: 15 working days depending on order vulume.

the exact schedule will be upon evaluating for each item.

Q: What is your terms of payment ?

A: Normally, Sample mold: 100% prepaid,

MP Mould: 50% deposit by T/T in advance, balance 50% paid before shipping MP samples.

Goods: 50% deposit, 50% before shipment.

If you have another question, pls feel free to contact us.

Q:What Information do we Need for Estimating Mold Cost and Unit Price?

A:1)3D drawing (igs.stp.prt file.); 2D drawing( jpg.Pdf.dwg.dxf. file) or samples

2)Materials demands(Solid Silicone or Liquid Silicone or Rubber)

3)Color demands (Pantone Color)

4)Hardness demands(Between 00~90A)

5)Package design Demands(Normal PE+Cartons for transporting)

6)Order quantity demands

7)Others: Special demands

Contacts

we are specialized in R&D and production of every product basing on clients'design or idea totally.

OEM Part Description

| Part Name | OEM Manufacturer Customize Molded Silicone Rubber microphone noise filter covers |

| Service | OEM OR ODM( Can design from clients' idea) |

| Part Material | Solid Silicone rubber or Liquid silicone |

| Material Hardness | 00~90 Shore A |

| Size | Customized |

| Shape | Customized |

| Color | Customized according to Pantone colors for silicone rubber material |

| Appearance | Comply with customer's requirement |

| Drawings | 2D OR 3D OR Samples are acceptable |

| Temperature Resistance | -40~300 degree centigrade |

| Tolerance | 0.01mm~0.15mm |

| Technology | Hot pressing molding or injection Molding or cast molding |

| Second Processing | Vulcanizing/ Deburring/Silk-screen/Carving/printing etc |

| Quality control | Internal QC control or 3 party inspection or clients' appointment |

| Part Feature | Colorful ,Anti-aging, good flexibility, good elasticity, Adjustable hardness, waterproof etc |

| Material grade | FDA or LFGB |

| EOQ | Basing on clients' demand |

| Shipping ways | 1. By sea from Shenzhen port or Guangzhou port. 2. By express: DHL/UPS/FEDEX ,etc 3. By air |

| Package | Normally PE bag+carton or customized as customer's request |

| Trade Term | Ex-works; FOB Shenzhen/Guangzhou ; CIF etc |

| Payment Term | Sample mold: 100% prepaid,MP Mould: 50% deposit by T/T in advance, balance 50% paid before shipping MP samples |

| Goods: 50% deposit, 50% before shipment | |

| Lead time | 5~15 working days for first article,10~25 working days for MP parts (depends on part structure ) |

| Specification | Confirm to ISO-9001 and ROHS Directive Compliant Green Products |

OEM Relative Projects

Manufacturer Strength Showing

Manufacturer Certificates showing

OEM Advantage Description

| 1. With 26 years experience, we are the one of the earliest factories which produce silicone rubber parts and related products in Dongguan, China, have strict process to control the quality and schedule to produce, which can offer you the prompt leadtime for 100% customer satisfaction. |

| 2.We can provide customer one-stop service from 3D drawing design or revise--mold design -- tooling making--Molding -- Second processing -- appearance treatment -- packaging--Outgoing, which help our customer to save time & money. |

| 3.The second processing are performed such as assembly, silk printing, spraying , PU coating ,laser etching etc if need be. |

| 4.Our sale & engineer teams are flexible and experience to provide customers with engineering and technical support all the time. |

| 5.Our molding machines ranging from 100 to 400 tons including compression machine, injection machine and cast channel more 40 sets. |

| 6.Our factory comply with ISO9001&ISO14001 Standard for all customers. |

| 7.We continuously strive to work out feasible solution to improve our production capacity and skills never end. |

OEM process showing

OEM Scope Showing

FAQ

Q: Are you trading company or manufacturer ?

A: We are OEM factory of customizing solid and liquid silicone rubber products and related products.

Two options: #1.. Make tool and produce products according to your own design.

#2.. Design 3D file basing on your idea, sketch or samples then go through #1.

Q: what is the color standard we are using?

A: Pantone color and RAL color or color chip.

Q: How long is the production circle?

A: Normally,Test mold: 5~15 working days, MP mold:10~25 working days;

Mass production: 15 working days depending on order vulume.

the exact schedule will be upon evaluating for each item.

Q: What is your terms of payment ?

A: Normally, Sample mold: 100% prepaid,

MP Mould: 50% deposit by T/T in advance, balance 50% paid before shipping MP samples.

Goods: 50% deposit, 50% before shipment.

If you have another question, pls feel free to contact us.

Q:What Information do we Need for Estimating Mold Cost and Unit Price?

A:1)3D drawing (igs.stp.prt file.); 2D drawing( jpg.Pdf.dwg.dxf. file) or samples

2)Materials demands(Solid Silicone or Liquid Silicone or Rubber)

3)Color demands (Pantone Color)

4)Hardness demands(Between 00~90A)

5)Package design Demands(Normal PE+Cartons for transporting)

6)Order quantity demands

7)Others: Special demands

Contacts